In order to meet the growing demands for cloth bags used in Bull Tobacco packaging and in an effort to cut costs by processing cotton in-house, Golden Belt Manufacturing Company was born in 1887. Getting its name from the region of Piedmont soils where bright-leaf tobacco could be grown, Golden Belt began as a single room. Workers consisted primarily of women and children, who were hired to sew cloth bags by hand. Many of these women would work out of their own homes as private contractors.

With the growth of the tobacco industry, the demand for these bags increased in quantity. A growing need for more efficient production resulted in Julian Carr establishing Durham Cotton Manufacturing Company, his first textile mill, to increase cloth output. Carr also commissioned William H. Kerr to design a machine to cut and sew cloth in 1885. Eventually to be mechanized in 1912, this machine reportedly did the work of up to 42 women.

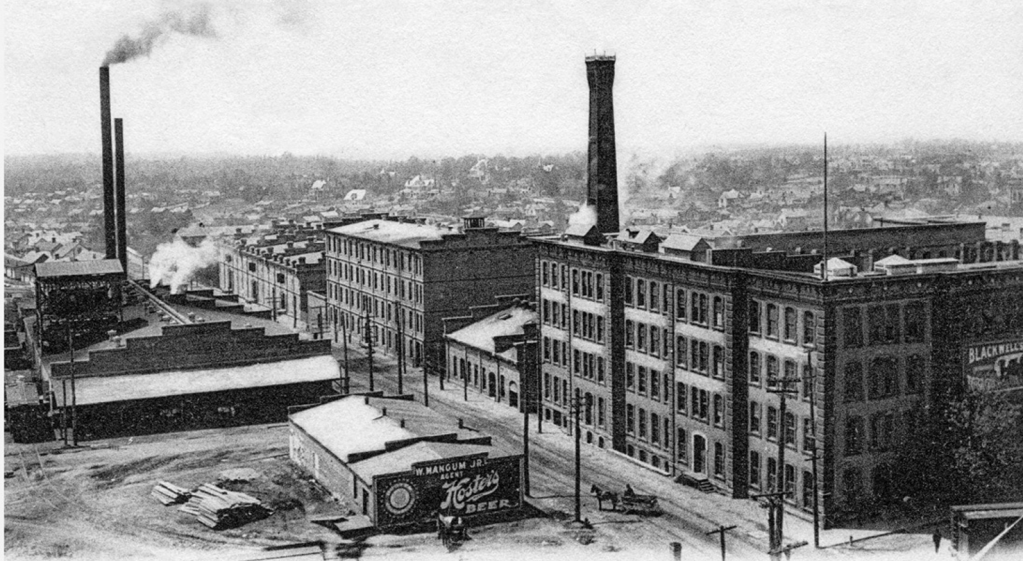

As Durham’s economy took off during the Industrial Revolution, Blackwell and Carr’s tobacco and cloth-and-bag-making output grew rapidly. By 1900, Golden Belt had 48 machines producing 15,000 bags each day (up to 2 million per month). As Golden Belt automated, it also diversified, adding sacks of flour, cornmeal, and salt to its offerings.

The mill would continue to expand across nearby roads and into vacant buildings, such as on East Pettigrew between Mangum and Roxboro Streets and across the Durham Hosiery Mill No. 1 at Angier and Main Streets in 1901. The factory was divided into a cotton mill and a bag mill, and the company constructed 50 mill houses east of the facility to house employed families. These buildings were packed with enormous steam-powered machines driven by leather belts. It was incredibly demanding, hot, loud, and dangerous work, often lasting 12–18 hours each day. Buildings continued to be added as World War I increased the factory’s business.

The 1930s marked a shift for the textile industry nationally, but especially in East Durham. The increased value of imported hosiery and the shift away from cotton to silk diminished the market for cotton products manufactured in Durham. As threats of work strikes occurred throughout the United States due to this market decline, textile mills across Durham shut down on September 1st, 1934, save for Golden Belt, out of concern that closing the mill would simultaneously shut down American Tobacco. These strikes would eventually end with concessions on September 25th.

Despite this, the decline in the textile industry continued locally. Golden Belt, due to its connection with American Tobacco Company, remained somewhat insulated from the decline and was able to maintain its output during the 1930s and continue to expand its operations and campus. However, as demand for bagged loose-leaf tobacco ended in the early 1940s, Golden Belt made a shift in production toward paper, packaging, and labeling (while also maintaining textile output), as well as gravure (rotary pressing) printing for cigarette labels.

In 1954, the company offered all of the surrounding mill houses to their occupants for 10% under their appraised values.

By the 1960s, Golden Belt expanded its production to include plastic as demand increased. This expansion included 34,000 square feet of additional space in 1966, and molded plastic cigarette filters and orange flavoring for tobacco bags were also added to production.

In 1995, Brown and William Tobacco Co. acquired American Tobacco and eventually broke apart the company. Golden Belt Campus was then donated to Durham Housing Authority in 1996. Eventually, Andy Rothschild of Scientific Properties bought the Southern portion of the complex from Durham Housing Authority and proposed redevelopment of the complex to include artist studios, apartments, retail, and office space in 2004. The entire campus was eventually resold to LRC Properties in 2016, and Justin Sacco took control to renovate it once more with the help of Alliance of Architecture to create the campus we see standing today.

All images courtesy of Justin Sacco unless otherwise stated